Conversion Coating of Aluminium

Pretreatment of aluminium materials, aslo called conversion coating of aluminium, plays an important role in terms of subsequent paint adherance or corrosion resistance, on its own without subsequent application or aesthetic and attractive appearance.

Conversion coating on aluminium can be basically in 3 different forms: chromate coating, tri-cationic zinc phosphate coating and aluminium phosphate coating.

Chromate Conversion Coating

Aluminium and aluminium alloys are treated by a corrosion resistant conversion coating that is called "chromate coating" or "chromating". General method is to clean the aluminium surface and then apply an acidic chromium composition on that clean surface. Chromium conversion coatings are highly corrosion resistant and provide excellent retention of subsequent coatings. Different type of subsequent coatings can be applied to the chromate conversion coating to produce an acceptable surface. Along with providing high corrosion resistance and paint adhesion properties to aluminium surface, it is well known that the visual desirability may be improved by forming a chromate coating by contacting the surface with an aqueous conversion coating solution containing chromium ions and other additives.

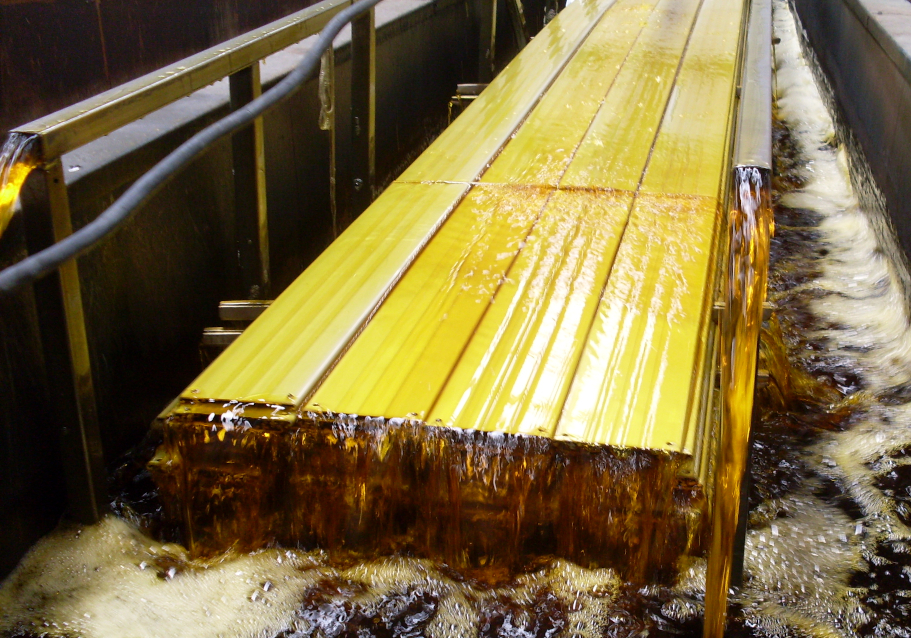

Quality of surface pre-treatment prior to powder coating is the most important factor that effects to stability of paintings. Properly pre-treated aluminium surfaces become highly protected against corrosion even if the surface is exposed to external impacts ( damage, high temperature, humidity…etc. ). Chromating is generally used as under paint protection. Coating weight on the surface varies between 0.2 -2.0 gr/m² when coating solution is applied to surface by immersion or spraying. Coating weight is variable according to concentration, application time, temperature and pH of the coating solution. Out of proper operation parameters coating weight quality of the coating will reduce. Thicker coating does not mean high quality coating.

Most commonly, chromating is provided by yellow chromating (Cr+6), green chromating (Cr+3), transparent chromating (Cr+3).

Coating quality will be effected positively when surface treated with deionized water after chromating. Refinishing of the rinsing baths also improve the quality of the coating. Chromated and rinsed aluminium workpieces should be dried in driers or ovens but it is important not to set drying temperatures above 70°C. After all these treatment workpieces are painted then cured 10 – 15 minutes at 200°C for subsequent application of powder coating.

Process line of chromate conversion coating can be set up as follows:

Simple Process

- Acidic Degreasing

- Water Rinsing

- Water Rinsing

- Chromating

- Water Rinsing

- Drying

Advanced Process

- Degreasing

- Water Rinsing

- Caustic Treatment

- Water Rinsing

- Nitric Acid Treatment

- Water Rinsing

- Chromating

- Water Rinsing

- Drying

Tri-Cationic Zinc Phosphate Coating

In the automotive manufacturing industry or any other metal body production, AlMg and silicon-containing AlMg alloys are used in some parts along with steel. In such works, specific zinc phosphate coating is used for entire coverage in order to eliminate adhesion and corrosion problems for subsequent painting.

Zinc phosphate coating on aluminium creates a uniform light gray and fine crystalline appearance. Unlike other zinc phosphate coating solutions, the fluorine content should be analyzed regularly and stable bath work should be provided with additives when necessary.

Aluminium Phosphate Coating

Aluminum phosphating is generally applied to create a dark and matt appearance on the surface. After the phosphate coating, protective oil treatment is carried out to prevent oxidation.

It is especially applied to aluminum parts such as pistons working in oily environment. The phosphate layer on the outer layer of the aluminum part prevents the abrasion of such parts that are in constant motion.

As in typical phosphating lines, there should be no contamination such as oil, oxide layer on the surface before phosphating process. For this reason, degreasing and acid etching processes are applied.